If you need any help, please feel free to contact us

- Silver Alloy Electrical Contact Materials

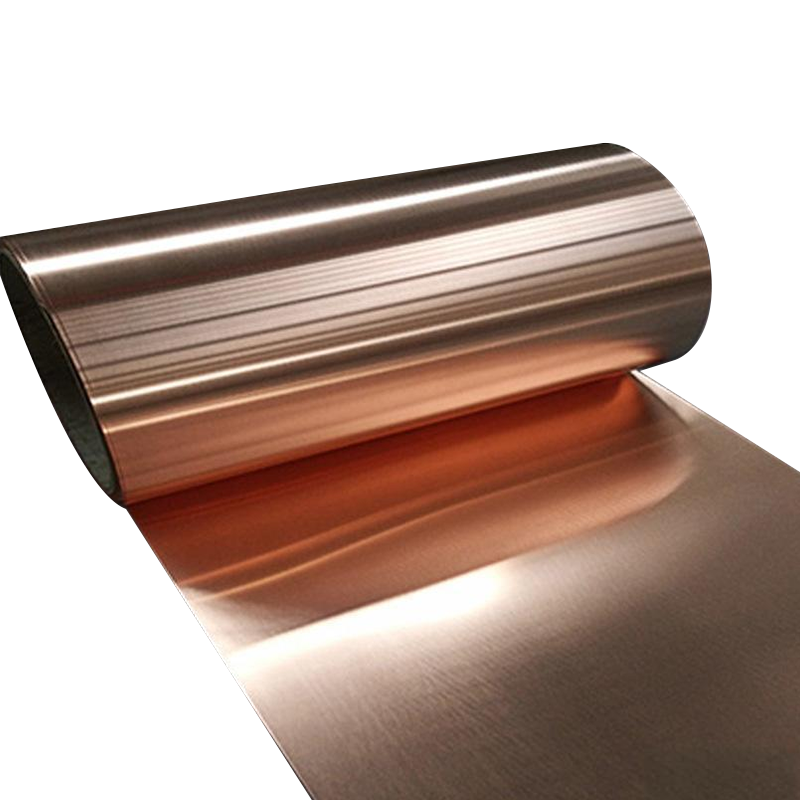

- Copper Alloy Electrical Contact Materials

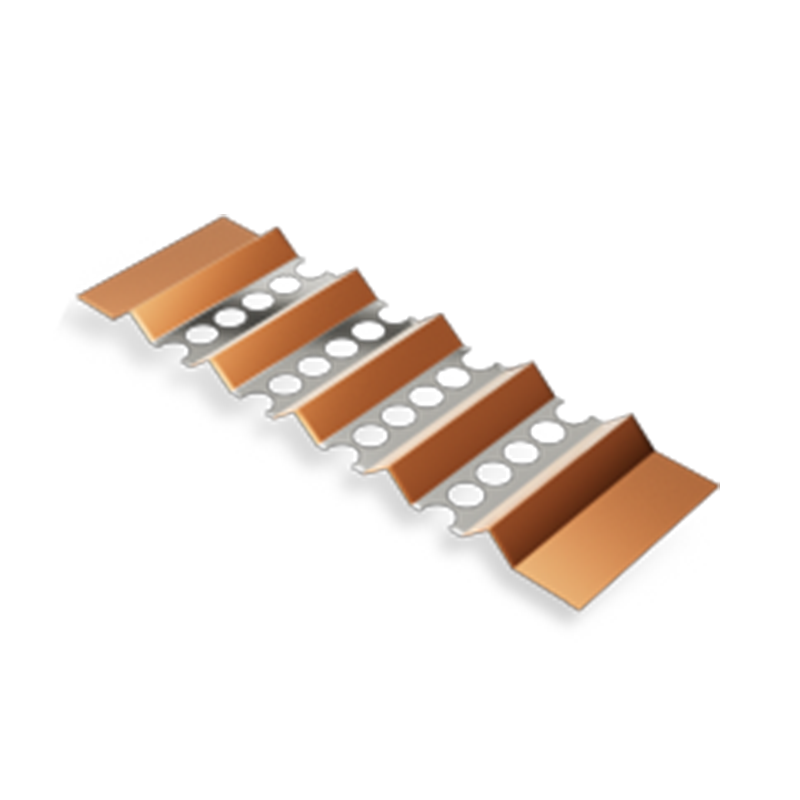

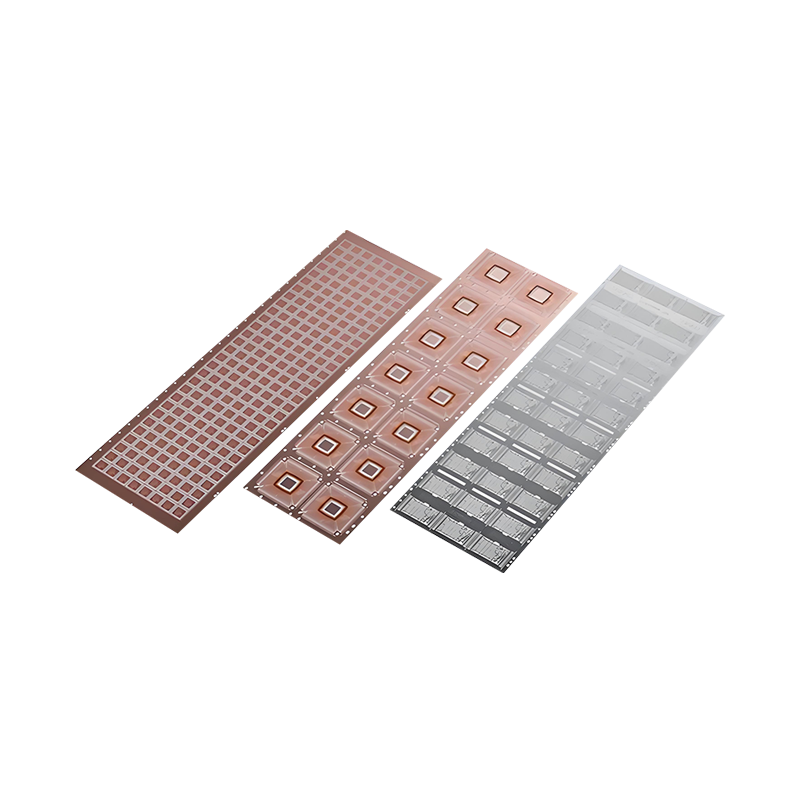

- Multi-layer Composite Materials

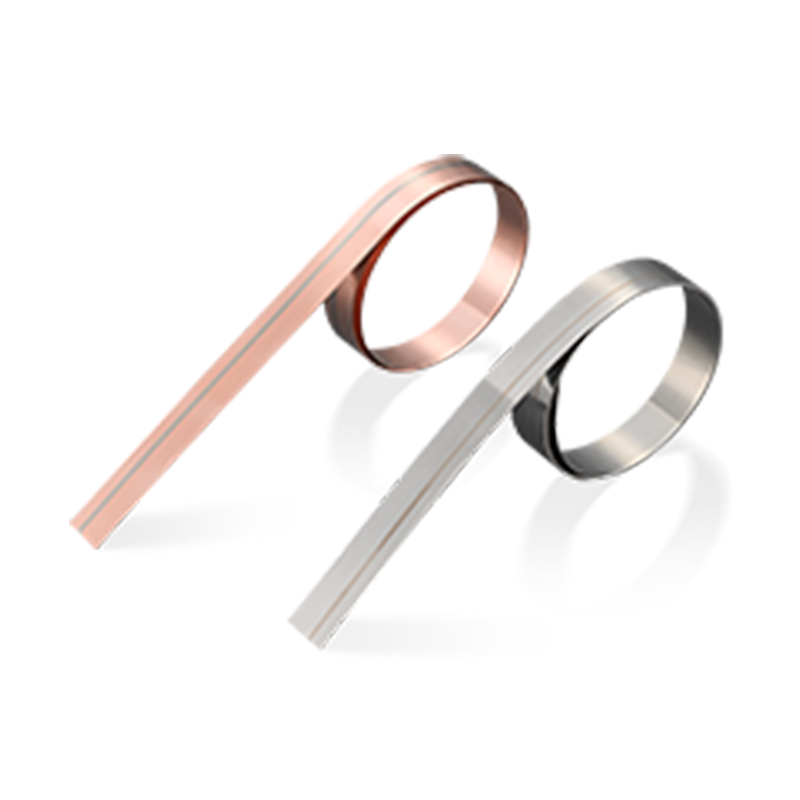

- Special Type Of Wire

- Thermal Bimetal Material

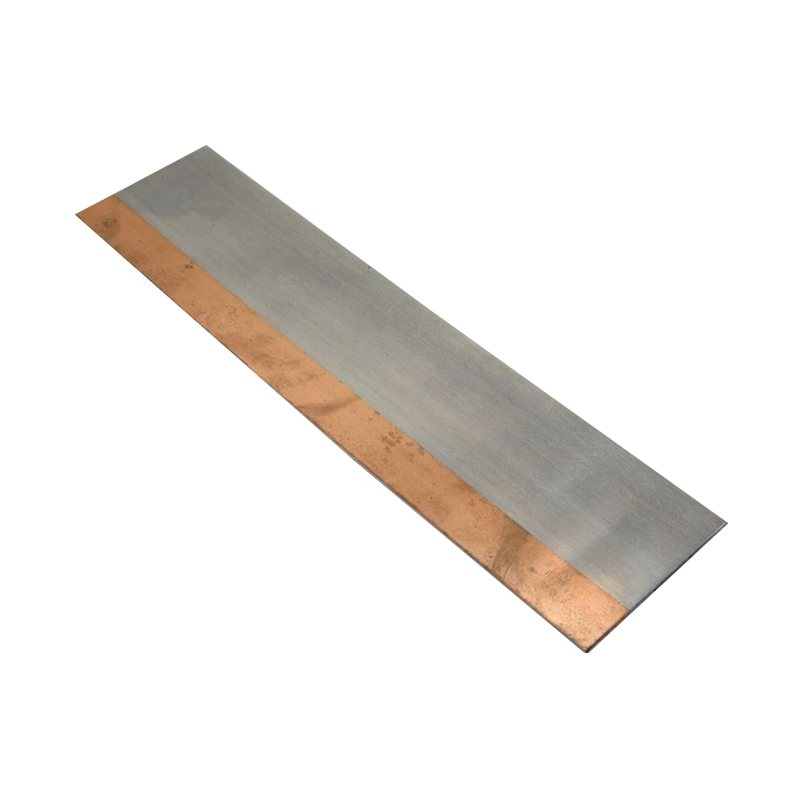

- Copper Steel Composite Material

- Copper Aluminum Composite Material

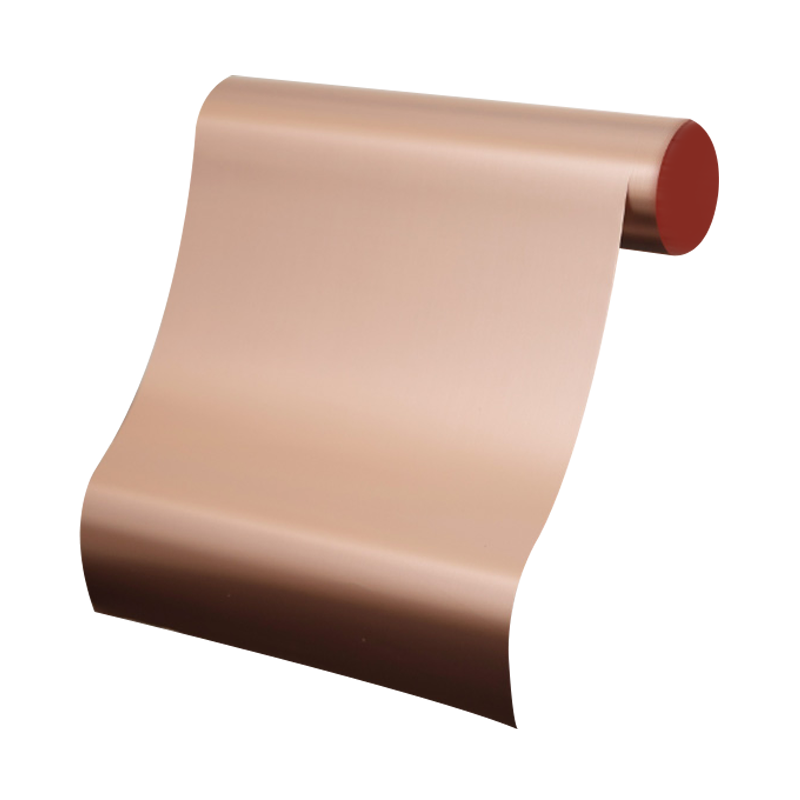

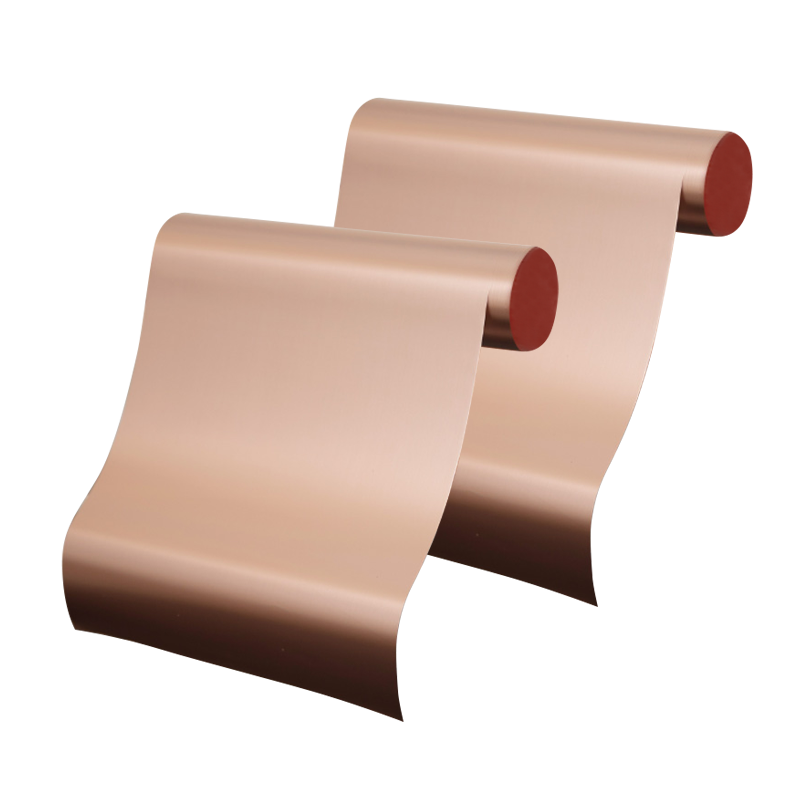

- Silver Copper Composite Material

- Copper Nickel Composite Material

- Aluminum Nickel Composite Material

- Aluminum Steel Composite Material

- Noble Metal Complex

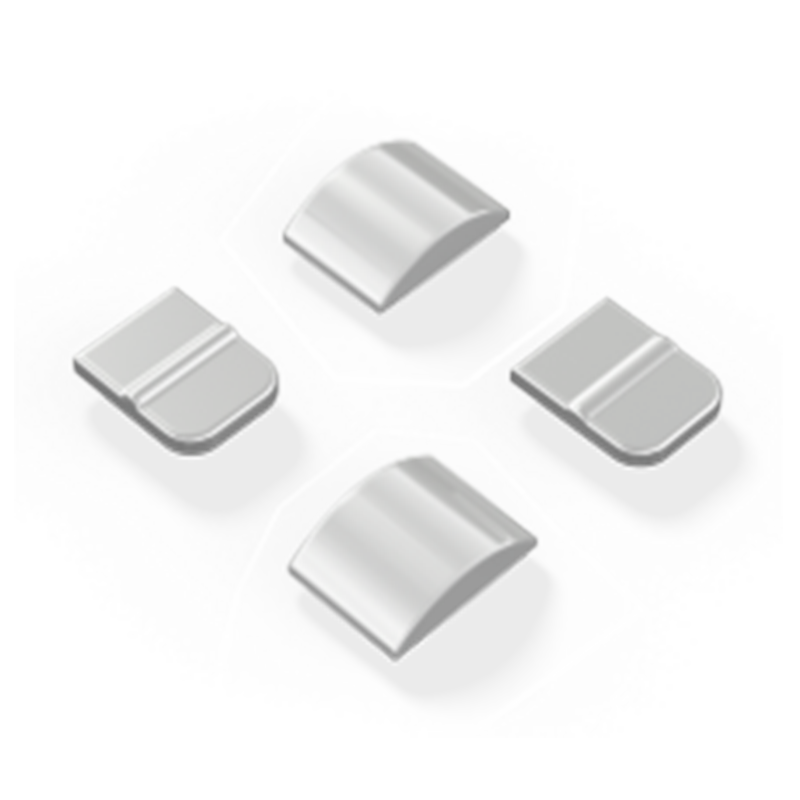

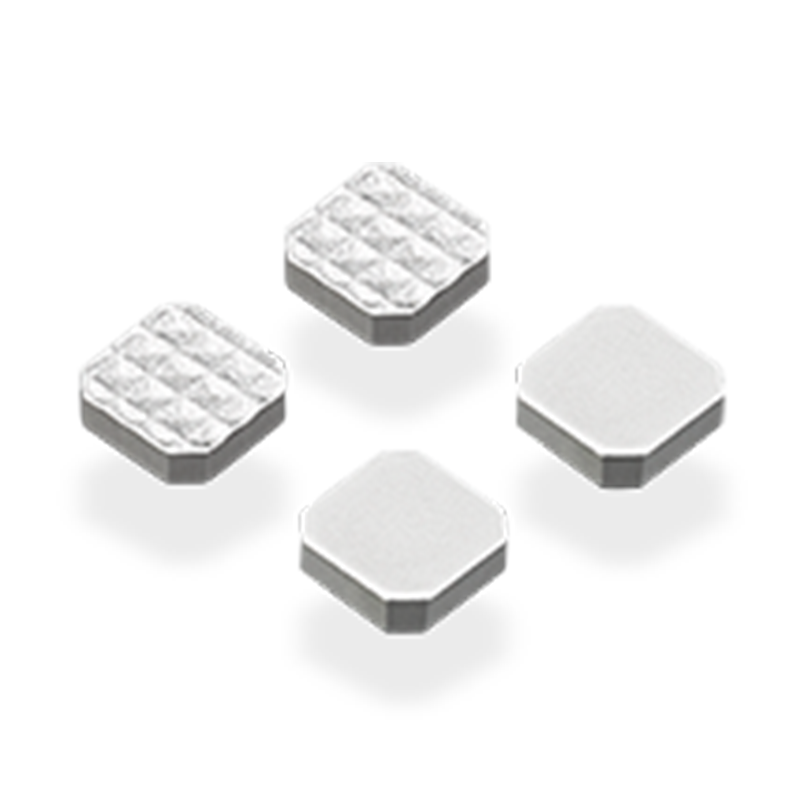

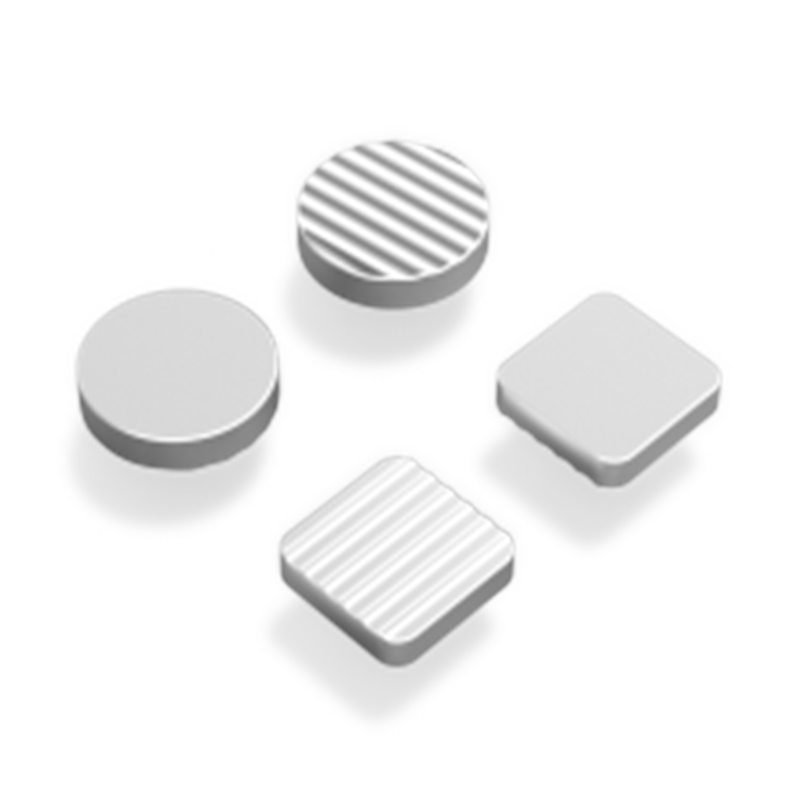

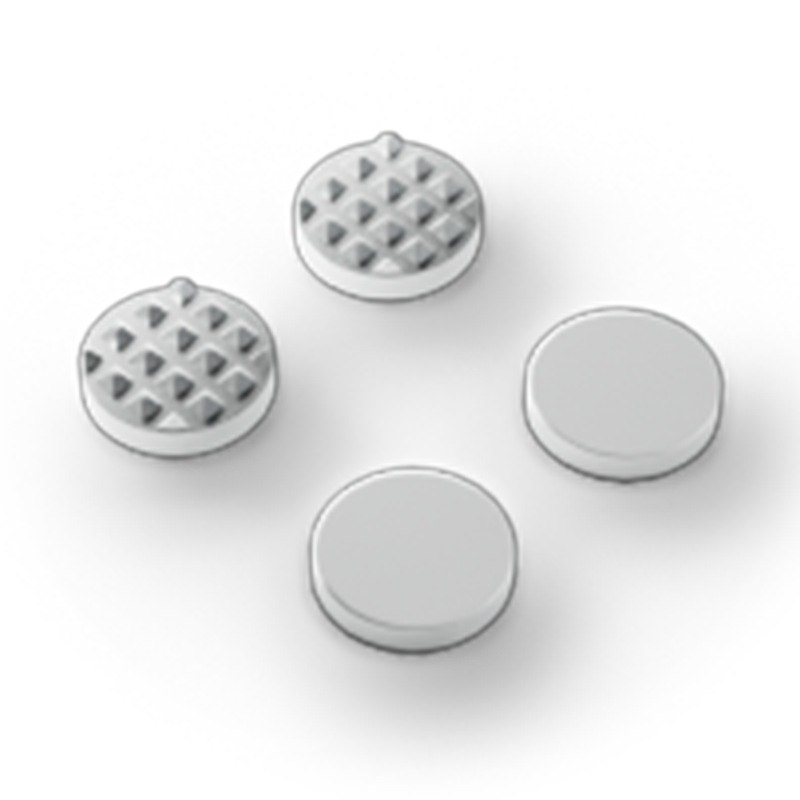

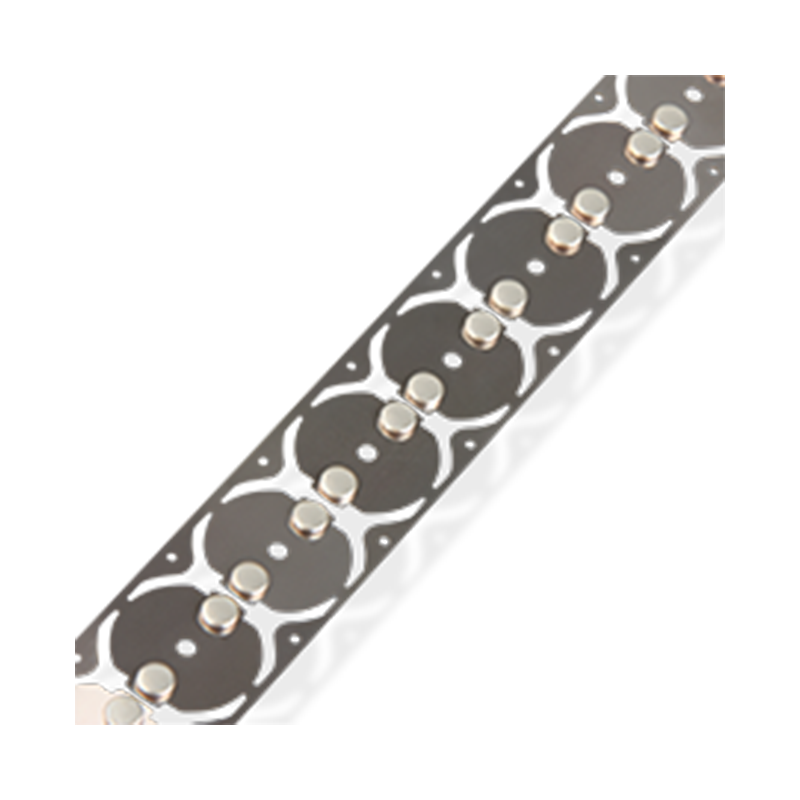

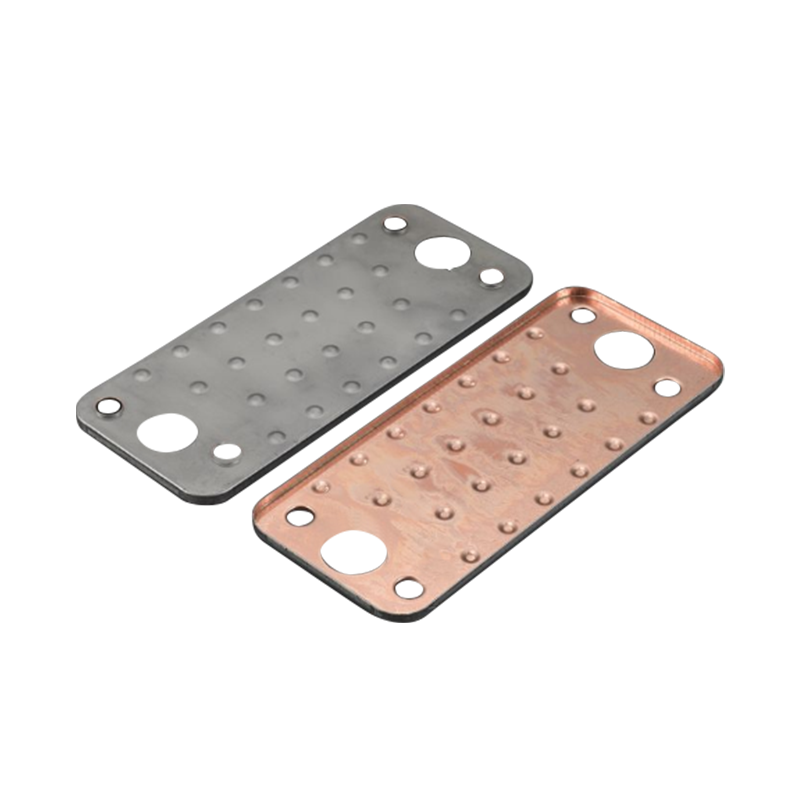

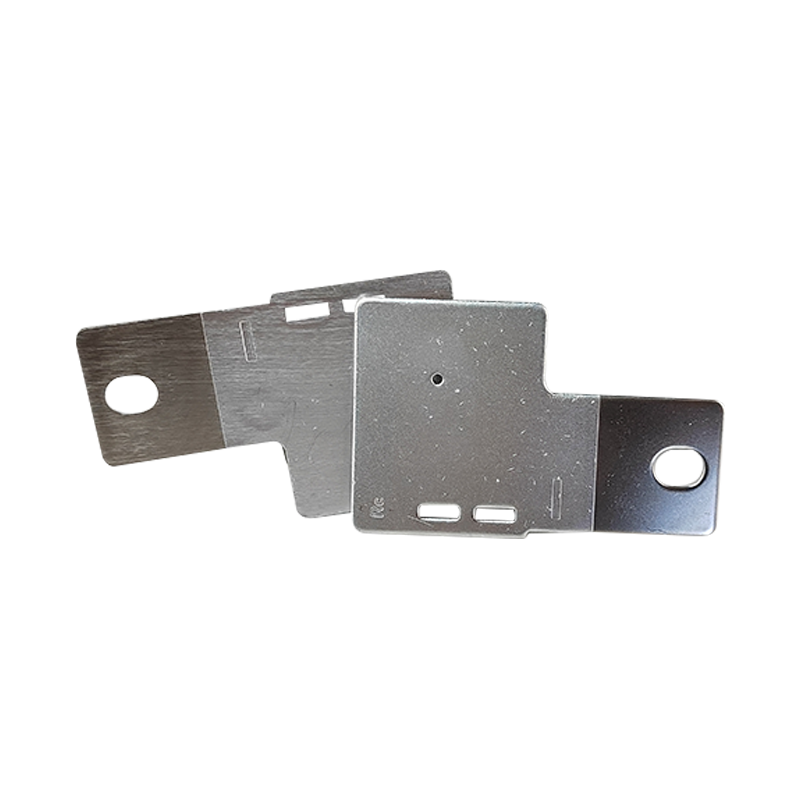

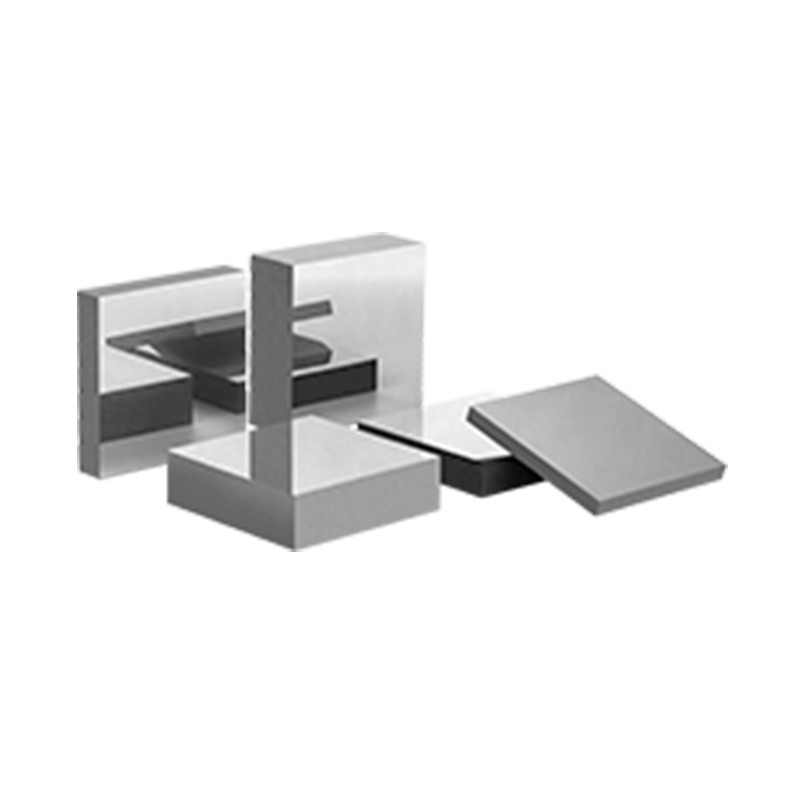

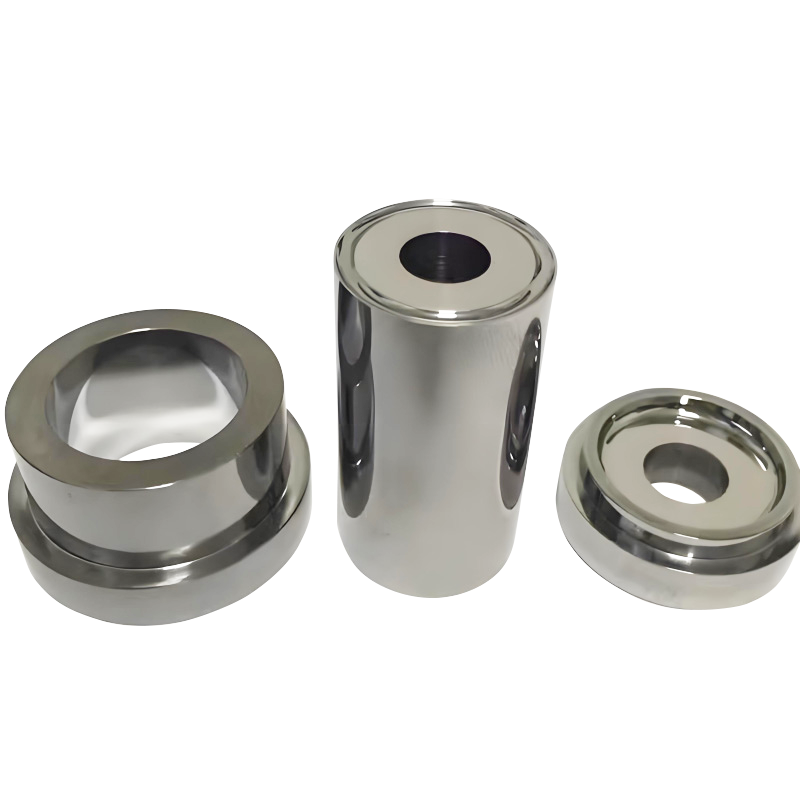

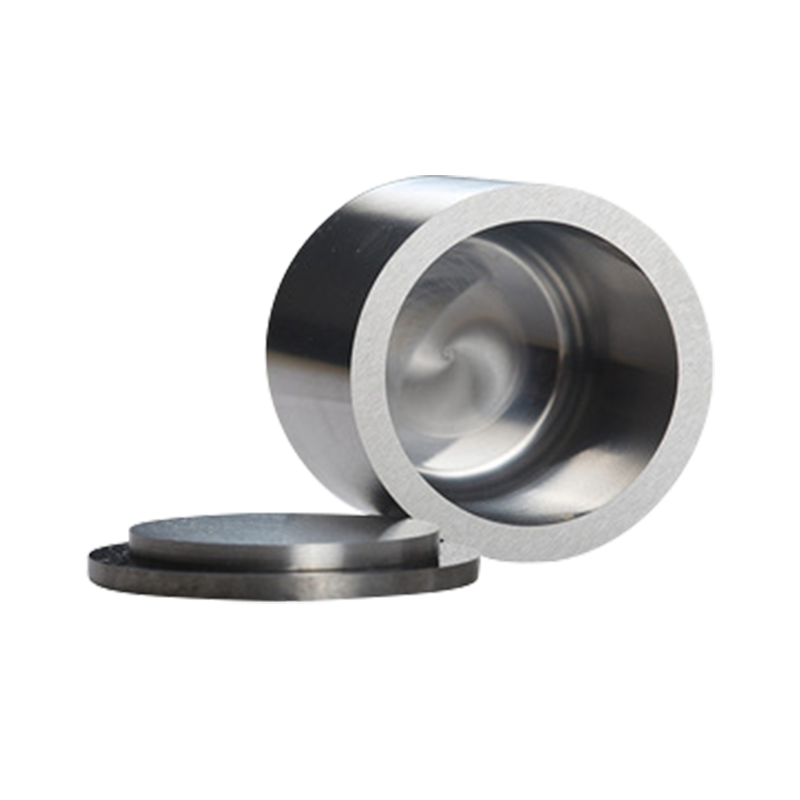

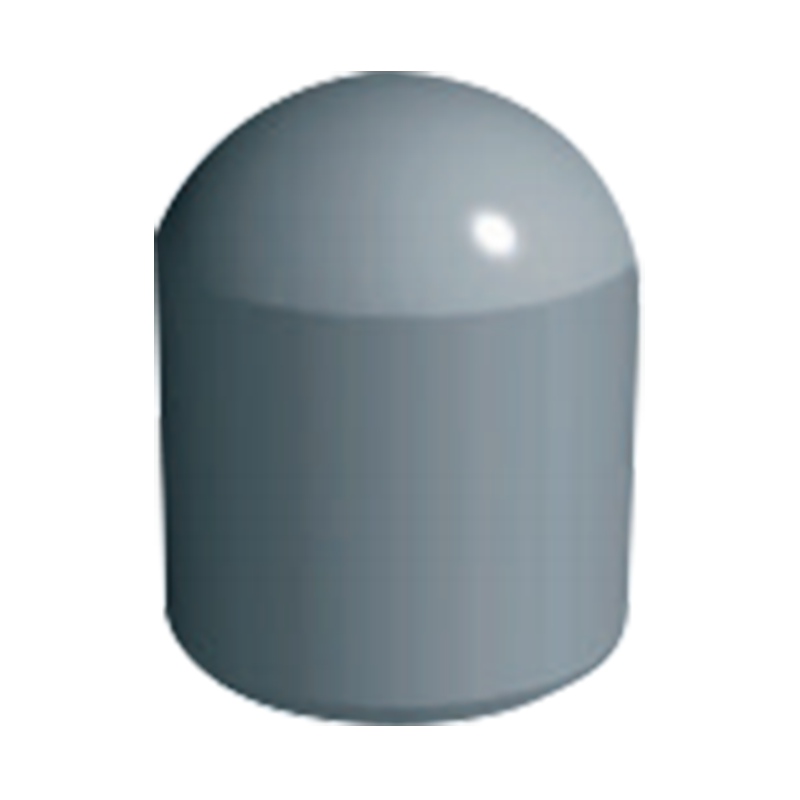

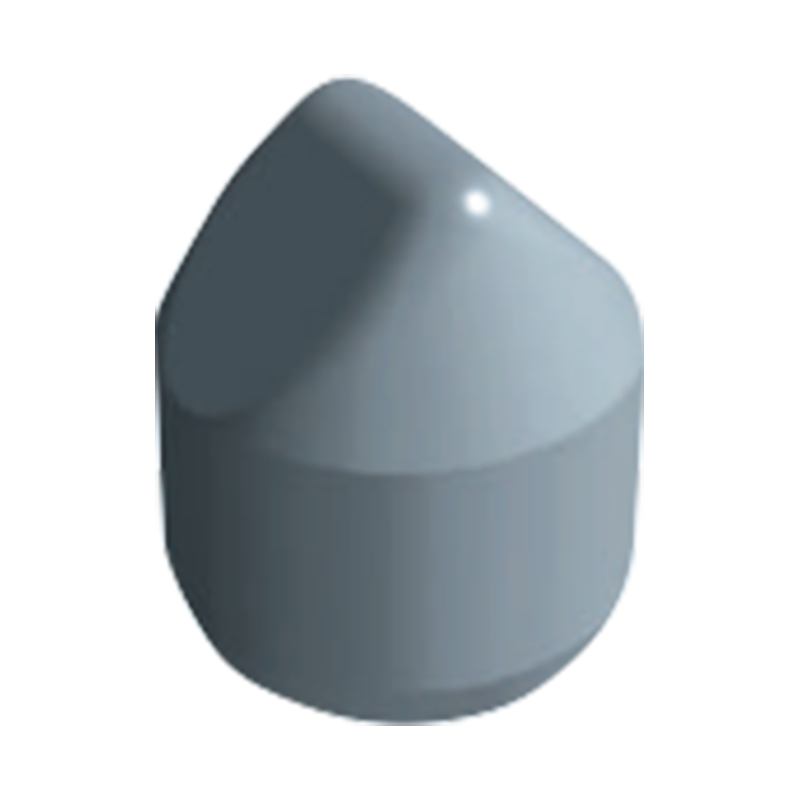

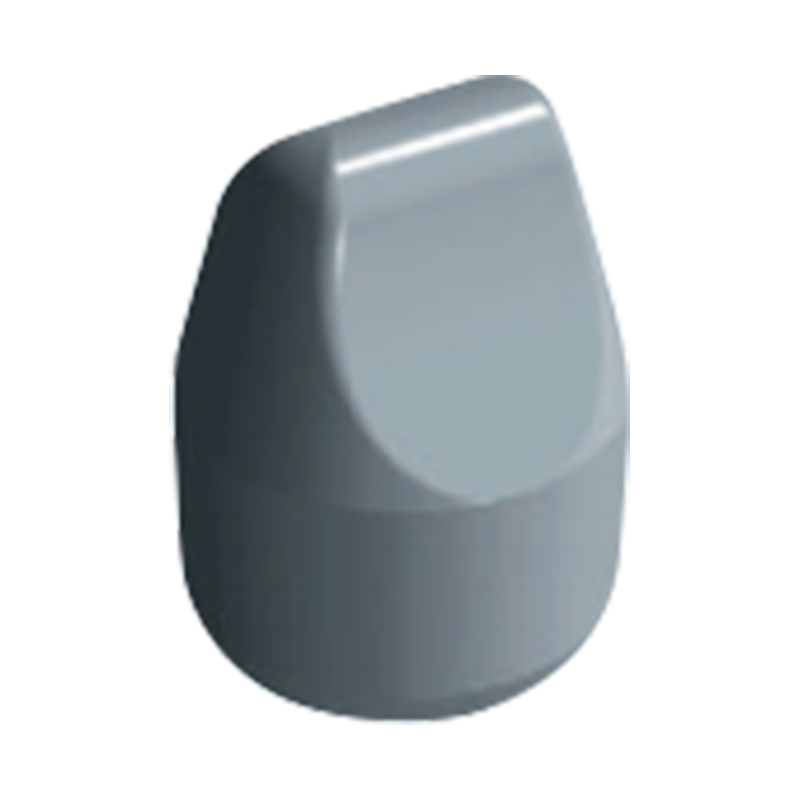

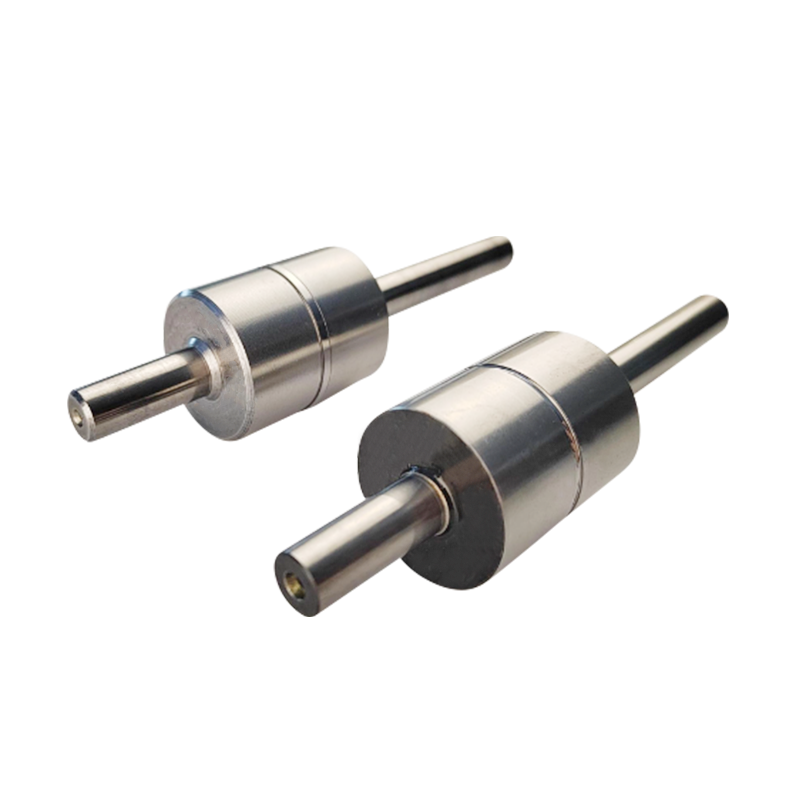

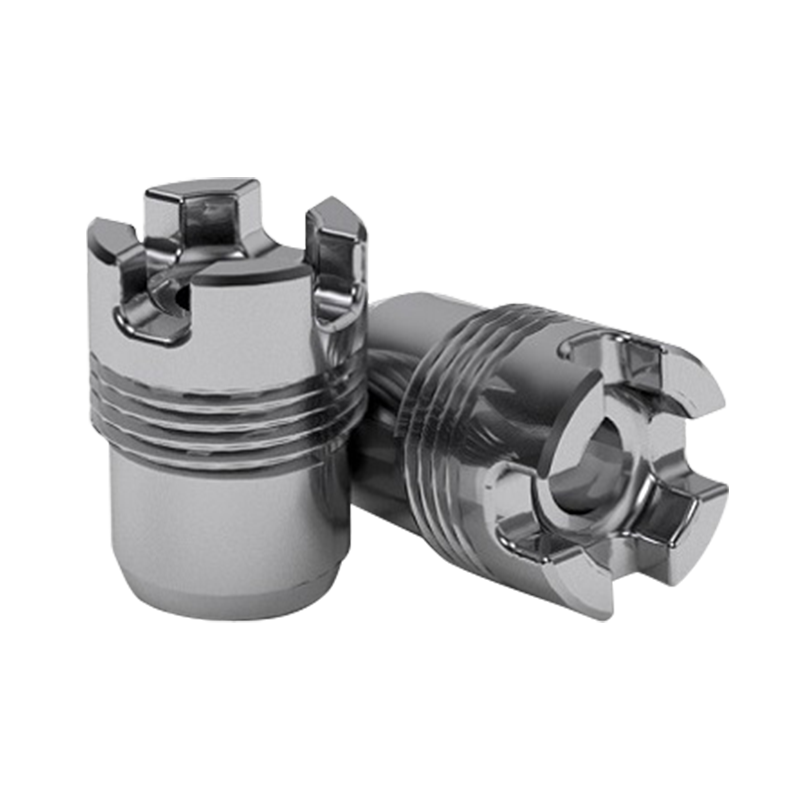

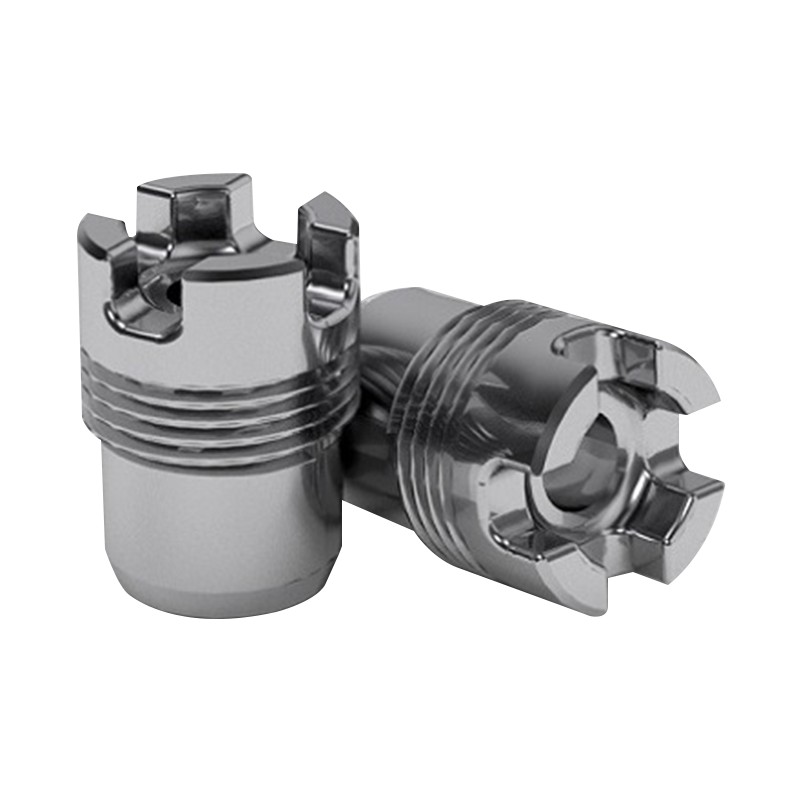

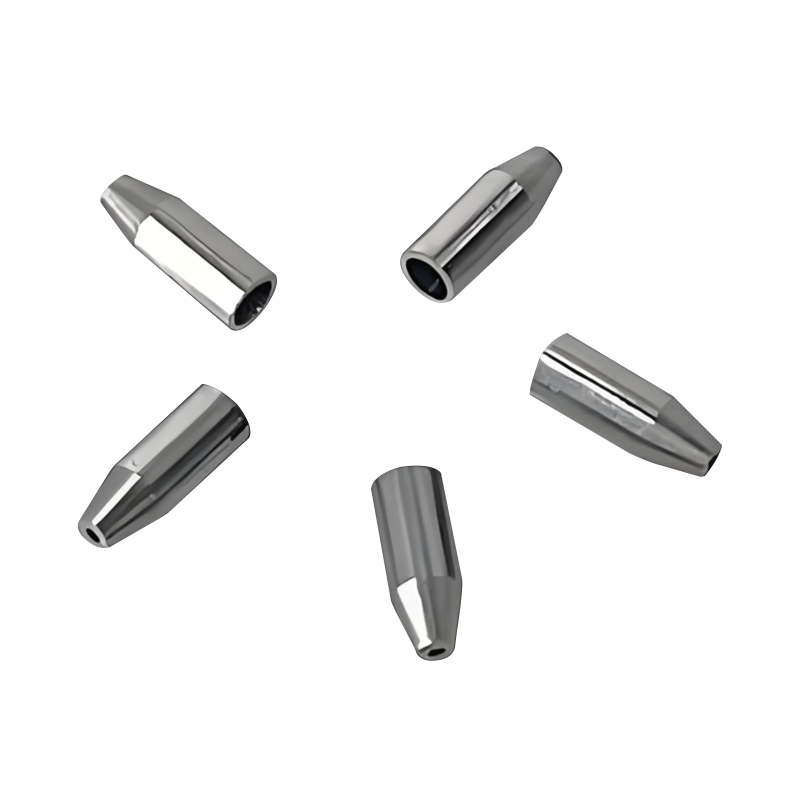

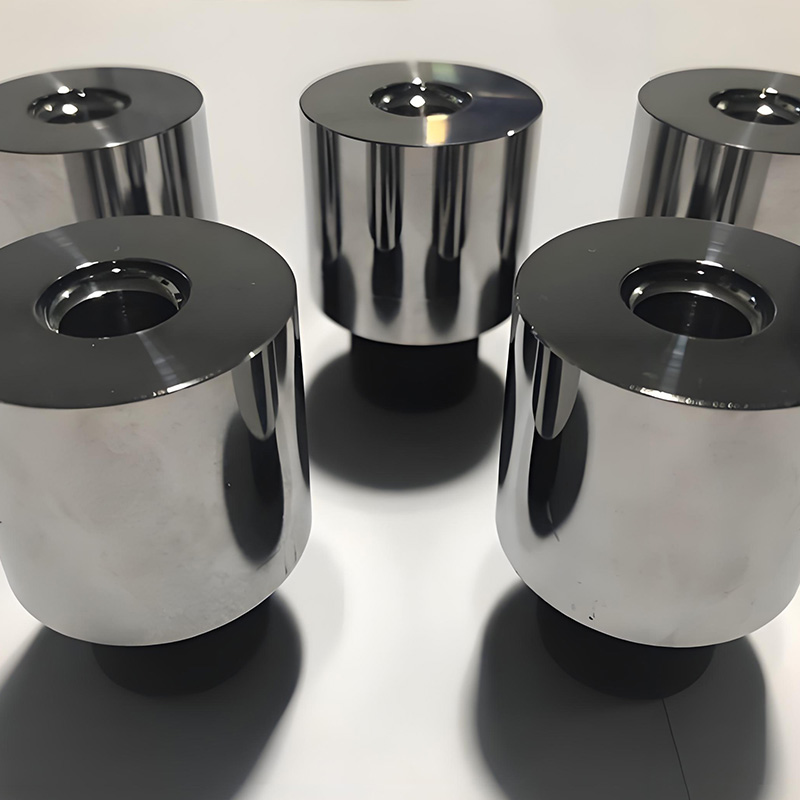

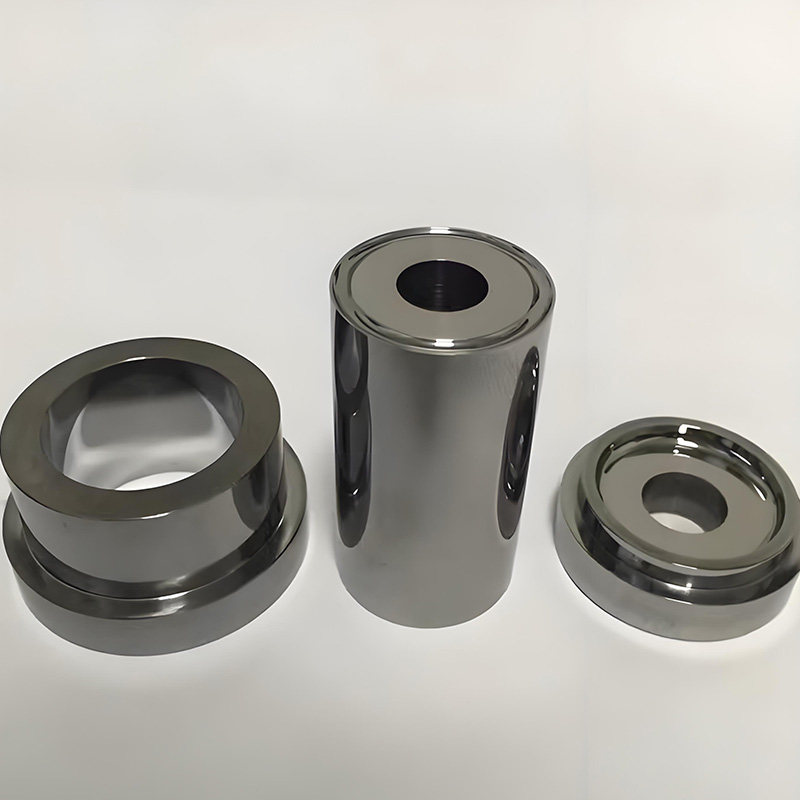

Battery Sealing Die

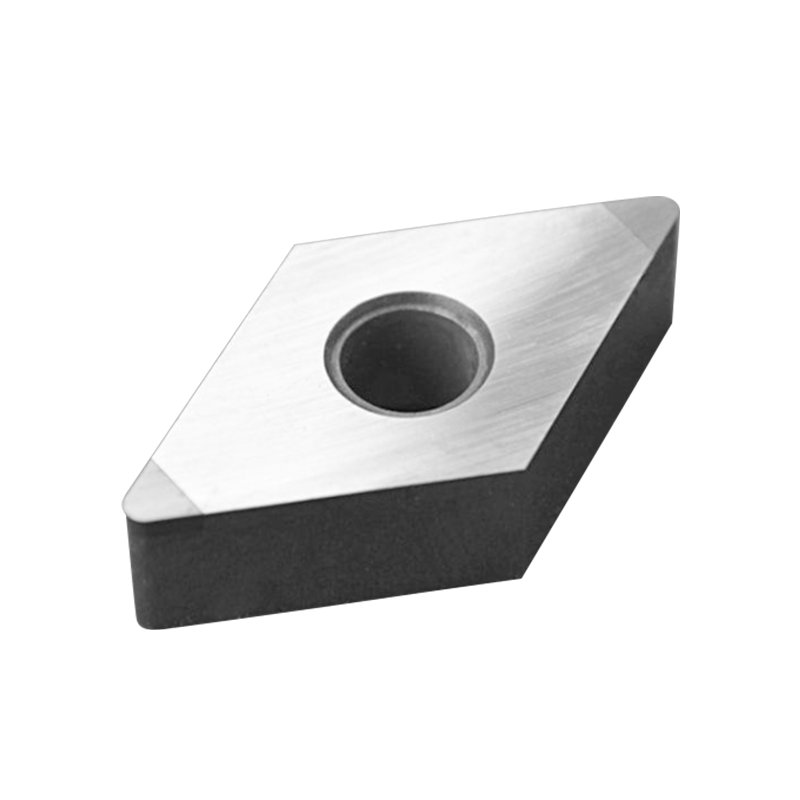

InquiryProduct introduction: The tungsten steel battery sealing die is made of high-quality tungsten steel mold material.

It is suitable for extruding aluminum battery cases on horizontal metal cold extruders and closed single-point presses. Tungsten steel die is made of high-quality tungsten steel mold material with the characteristics of acid and alkali resistance, corrosion resistance, and no rusting, the extruded aluminum battery case can get the smooth inner and outer surface, and the service life is more than 2.5 times the ordinary extrusion die.

Application areas: widely used in horizontal metal cold extrusion machines and closed single-point press.

| Grades | Grain size type | Cobalt content % | Hardness HRA | Density g/cm3 | Flexural strength N/mm2 |

| HU12U | 0.4 | 6 | 93.8 | 14.8 | 3900 |

| HU18U | 0.4 | 9 | 93 | 14.5 | 3900 |

| HU24U | 0.4 | 12 | 92.6 | 14.12 | 4200 |

| HU20X | 0.6 | 10 | 92.2 | 14.43 | 3800 |

| HU20 | 0.7 | 10 | 91.9 | 14.45 | 3800 |

| HU20E | 0.7 | 10 | 91.8 | 14.45 | 3700 |

| HU12 | 0.7 | 10 | 91.8 | 14.45 | 3700 |

| HF30F | 0.8 | 10 | 91.8 | 14.3 | 3500 |

| Grades | Scope of use |

| HU12U | Suitable for high hard material finishing, PCB drills, milling cutters, engraving cutters |

| HU18U | For hard and difficult to machine materials, stainless steel machining, miniature tools |

| HU24U | High speed milling grade, suitable for HRC55-60 alloy steel, stainless steel, non-ferrous metals, titanium alloy, high temperature alloy, etc. |

| HU20X | General-purpose high-speed milling cutter and drill material for alloy steel, stainless steel, cast iron, non-ferrous metals, high-temperature alloys, etc. |

| HU20 | General-purpose milling cutters and drills for alloy steel, stainless steel, non-ferrous metals, high-temperature alloys and other materials. |

| HU20E | General-purpose milling cutters and drills for alloy steel, stainless steel, non-ferrous metals, high-temperature alloys and other materials. |

| HU12 | High speed milling grade, suitable for HRC55-60 alloy steel, stainless steel, non-ferrous metals, titanium alloys, high temperature alloys and other materials. |

| HF30F | Economical milling cutter materials, suitable for alloy steel, non-ferrous metals and other materials. |

Wenzhou Hongfeng Electrical Alloy Co., Ltd. (hereinafter referred to as “Wenzhou Hongfeng”), founded in September 1997. The main products include electrical contact materials, metal-matrix engineered composite materials, cemented carbide materials, high-performance extremely thin lithium copper foil, and intelligent equipment, providing customers with integrated functional solutions from material research and development to component manufacturing, and then intelligent manufacturing. As Battery Sealing Die company in China, the products are widely applied in industrial manufacturing, intelligent transportation systems, smart homes, communication information, aerospace, mining, machinery manufacturing, medical, and other fields.From quotation to delivery, we provide one-stop customer service, respond quickly to customer needs, solve problems efficiently, and complete delivery; in addition, we can also provide professional material design, process optimization, sample preparation testing, mass production supply, and technical support through services such as professional material design, process optimization, and technical support. Meet customer needs for high-performance alloy materials.

-

Materials Design

Materials Design

And DevelopmentDesign and development of new alloy functional composite materials can be carried out according to customer needs and application requirements.

-

Manufacturing Process

Manufacturing Process

OptimizationThe manufacturing process of new alloy functional composite materials can be optimized for customers.

-

Sample Preparation

Sample Preparation

And TestingWe can provide customers with sample preparation and testing services for new alloy functional composite materials.

-

Mass Production

Mass Production

And SupplyOnce the new alloy functional composite materials are mass-produced and provide stable and reliable supply.

-

Technical Support

Technical Support

And ConsultingHongfeng can also provide relevant technical support and consulting services to customers. Battery Sealing Die Suppliers.

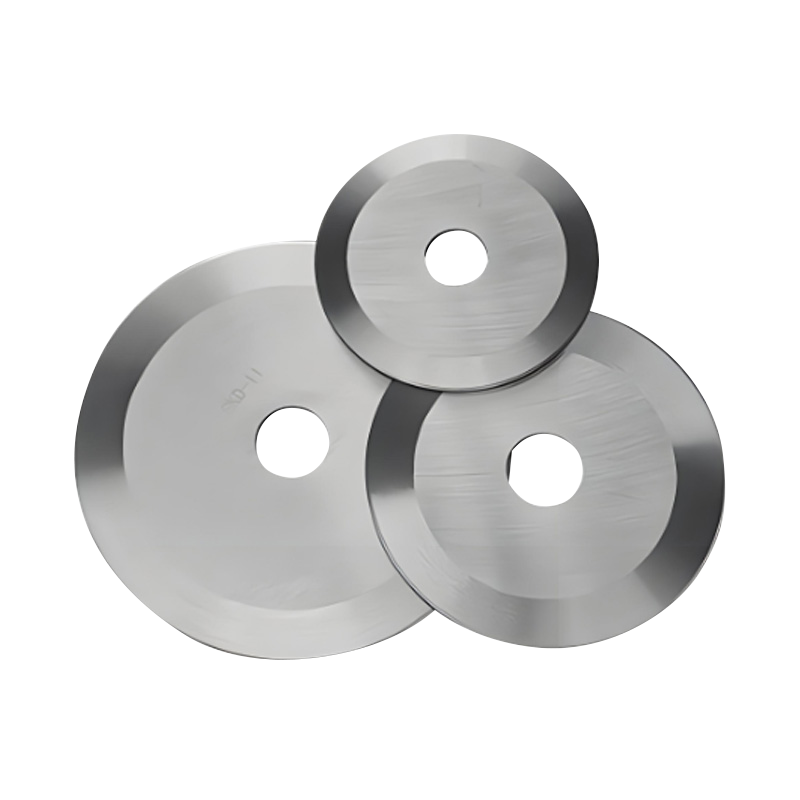

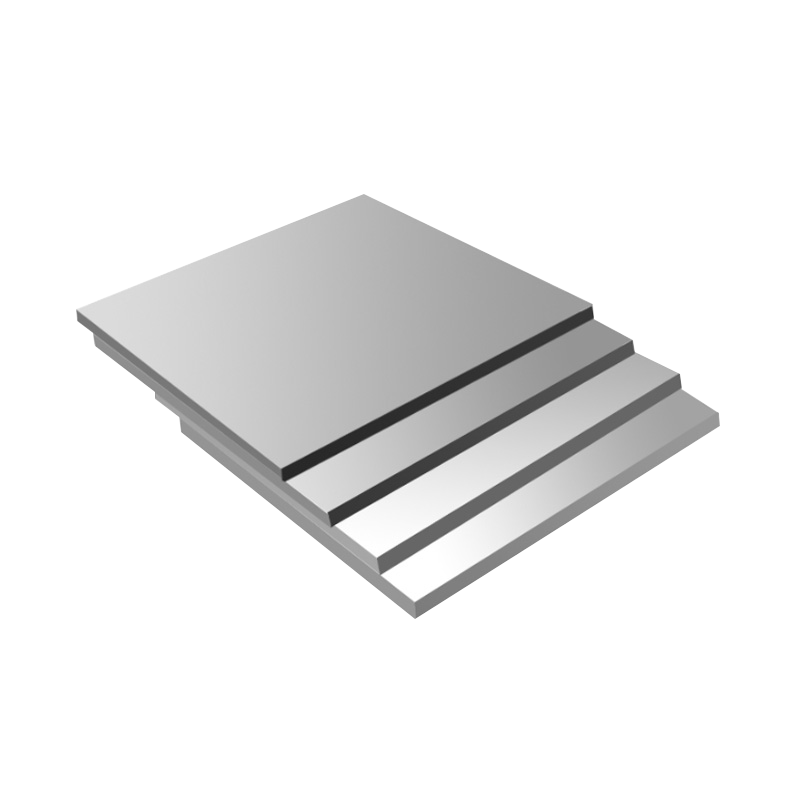

The performance of tungsten carbide plates is heavily influenced by the sintering process used durin...

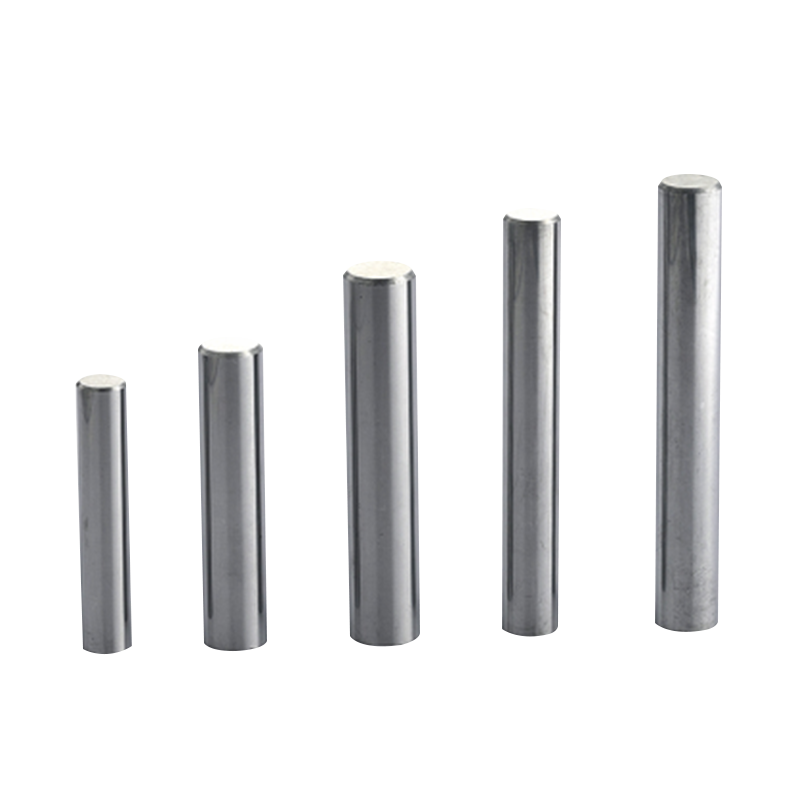

Introduction Tungsten carbide bars and rods are widely used in industries requiring extreme hardness...

IntroductionTungsten carbide plates are engineered components made from a composite material consist...

Tungsten carbide burrs are rotary cutting tools used in a wide range of industrial applications requ...

In the demanding world of industrial machinery, the reliability and efficiency of bearings are criti...

- Tel:

+86-18857735580 - E-mail:

[email protected]

- Add:

No. 5600, Oujin Avenue, Wenzhou Marine Economic Development Demonstration Zone, Zhejiang Province, China

Copyright © Wenzhou Hongfeng Electrical Alloy Co., Ltd. All Rights Reserved. WholesaleBattery Sealing Die Company

en

en English

English Deutsch

Deutsch